One of the issues owners of the latest platform from Arctic Cat have been chasing is that of drive belt durability. Since its introduction in 2012, the Arctic Cat Procross & Proclimb sleds have been tough on drive belts. Arctic Cat has taken several steps in an attempt to provide greater drive belt durability, with changes to their secondary clutches and changes to the drive belt compound and construction, but the longevity is still not what many owners would like.

Now add to the issue the added power of turbo kits and other modifications, and drive belt durability becomes even more of an issue. This is what the performance tuners at Evolution Powersports were faced with. They were selling the performance kits for these sleds, and riders were having issues with the drive belt durability. To them, it didn’t matter if the bone-stock sleds were also having issues, they needed to do something about it themselves and for their own customer’s satisfaction.

Evolution’s take on the drive belt durability issue is this – they tried many of the other products out on the market and found that none of these things made more than a so-so improvement in the drive belt life. Looking into the root cause of the issue, they believe it is a matter of certain sleds having materials that are substantially out of specification. When the out of specification items stack up, you have a belt blower.

For example, Evolution tested 10 different Arctic Cat motor mounts and the durometer values varied from 30 to 62. The jackshafts were the same – some were properly heat treated, and some were not up to specification. The consistency of the parts and pieces just isn’t there.

Lastly, some believe that in a rubber belt CVT system you cannot have a 100% solid connection between the clutches because the drive belts have very poor tolerance to shock load. In other words, when the clutches lose control of the drive belt and then grab it again, a decoupled engine will have a small amount of deflection to absorb some of the force rather than the drive belt absorbing 100% of it. Undoubtedly belts are weakened each time this happens with a solid connection.

Based on these observations, Evolution Powersports performed testing and has developed several stages of “Belt Life Improvement Products” that deal with these issues.

The first is their TCL elimination bracket. The purpose of this product is to decouple the engine from the jackshaft and go back to a more traditional engine/jackshaft layout. EVO has found that the stock wobble bearings along with soft jack shafts that deflect considerably when under load coupled with excessive engine movement are the primary causes of clutch misalignment and therefore poor belt life. With the TCL elimination bracket, EVO is supplying a traditional straight roller bearing. They are able to do this because the jackshaft is now fixed and aligned with the chain case jack shaft bearing. Once the movement is taken out of the PTO side, the top gear in the chain case will now stay in alignment with the bottom gear and chain. Chain & gear life are vastly improved once this movement is eliminated. You will notice that on the new SR Viper and 7000 series, Arctic Cat has completely abandoned the TCL and has set up their engine/jackshaft like this.

This product was tested all last year alongside control sleds to verify the improvements. By the end of the year, EVO had over 10 times the belt life that they had in the beginning, seeing well over 1000 miles per drive belt.

These kits are being sold in 3 stages:

Stage 1

Consists of the Turbie/EVO TCL elimination bracket and replacement PTO side quality SKF roller bearing

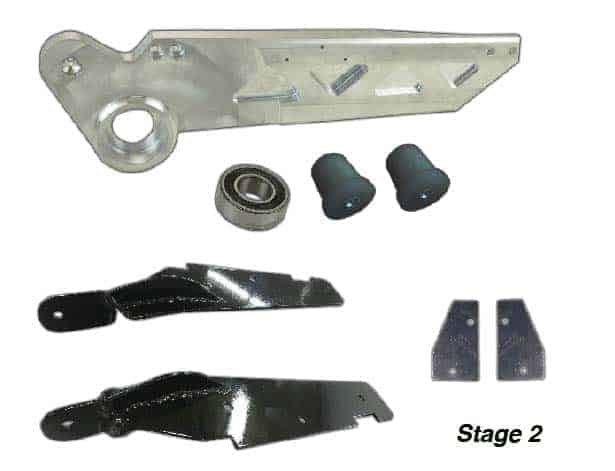

Stage 2

Is the above items with the Turbie/EVO supplemental Engine Braces with same durometer except solid instead of gear shaped motor mounts. The engine braces & motor mounts allow the engine to be held in securely without the concern of the heat exchanger tabs breaking off – the stock aluminum tabs on the heat exchanger are removed. The engine braces mount to the tunnel with rivets and bolts and have doublers in key areas for strength. The motor mounts have adjustable sleeves included in the kit and allow adjustment of both X&Y plane parallelism between the primary and secondary clutches. This also allows customers to dial in the required “positive offset parallelism” at rest so when the engine is being pulled backwards under load, the clutches will be parallel. For those who wish to keep their TCL in place, this allows needed adjustment to properly align the clutches.

Stage 3

Is the items in Stages 1&2 along with EVO’s new 300M jackshaft. This shaft has been strengthened in key areas. The 300M Alloy Steel resists bending and will do a far better job of keeping the secondary aligned with the primary. This shaft will allow the use of the stock 1100T gears (with reverse) and stock chain or EVO’s HD Link Belt chain. EVO has found that once the movement and angle changes of the top gear with respect to the rest of the gears & chain is eliminated (along with installing a manual chain tensioner) the gear & chain problems largely disappear.

The installation of this kit requires all of the skills necessary for removing the stock jackshaft and stock engine brace as well as pressing the bearings off and on the jackshaft. The stock brace will need to have the bearing pocket removed in order to allow fitment of the new TCL Elimination Bracket. This can be accomplished with a Sawzall and a bench grinder. Detailed instructions are supplied for those who have the capability to do this job.

For those who do not have the skills to do the complete job, you can send your existing TCL bracket to EVO for modification and your jackshaft for bearing removal and installation. The charge to do the cutting and grinding of your shaft as well as the pressing of the bearings is $100.00.

For more information or to have your sled upgraded contact Evolution Powersports in Stillwater, Minnesota at 970-680-3861 (evopowersports.com)

This article was originally from the December 2014 print edition of SnowTech Magazine. Subscribe to SnowTech Magazine and have all five issues per year delivered right to your door!